At RK Water, we specialize in providing custom water treatment systems to meet the unique needs of our clients. We take care of every part of the fabrication process, from identifying treatment needs to delivering a fully functional operational water treatment system.

Identifying Water Treatment Needs, Goals and Approach

Every custom water treatment project begins with a thorough assessment of site-specific treatment requirements. By understanding our client’s needs, we design comprehensive water treatment solutions that align with desired outcomes. This includes considering contaminant levels, flow rates, and water quality standards. Our team will engineer a system that meets or exceeds desired standards to meet environmental regulations. Based on the needs and treatment goals, RK Water will explore the best available technologies, such as reverse osmosis, medias, resins and chemical treatment.

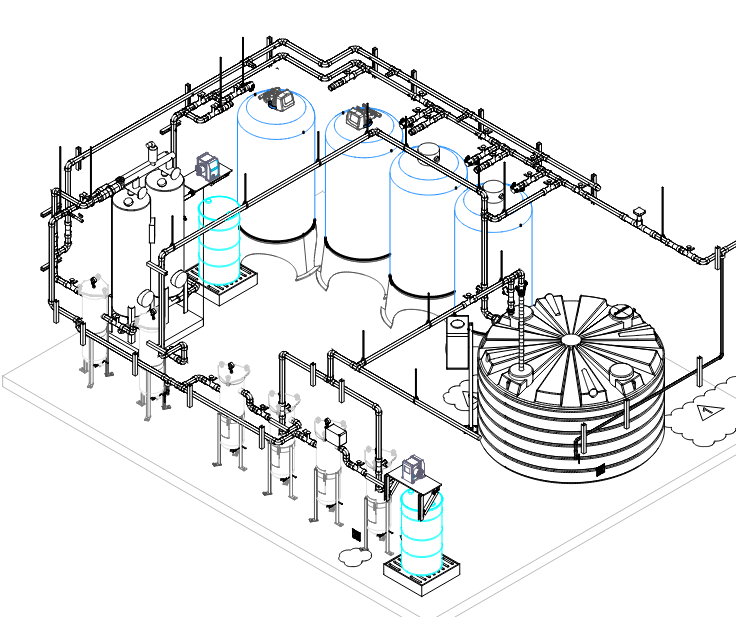

Creating Schematic Design and CAD Fabrication Drawing

With the treatment approach determined, our experienced engineers create a schematic design that serves as a blueprint, outlining the treatment system’s layout, equipment arrangement and process flow. Using cutting-edge CAD software, RK Water generates detailed drawings of the fabrication process. These drawings provide precise specifications for each component, including dimensions, materials, connections and assembly instructions.

Procurement, Fabrication and Testing

Our in-house team of plumbers and pipefitters will fabricate the designed water treatment systems. By working with other RK business units, we have the in-house capabilities and facilities to ensure every component is installed correctly and according to the design specifications. Once fabrication is complete and signed off, the completed fabricated system is carefully packaged and prepared for shipping to the installation site.

Operational Treatment System

If desired, the RK Waters field team will install the treatment system upon arrival at the site. Before system operation begins, we’ll ensure that all components are properly connected and calibrated, guaranteeing a smooth start-up sequence. Furthermore, RK Water offers ongoing operational and maintenance services, including technical assistance, to keep the treatment system operating at peak performance.

At RK Water, we understand that each water treatment project is unique and requires a tailored approach. Our fabrication process ensures that our clients’ water treatment goals are effectively and efficiently achieved. If you’re looking for a reliable partner in water treatment, count on RK Water to provide comprehensive solutions.

Learn more at rk-water.com.

Steel is the backbone of innovation and economic growth for most of this country’s infrastructure. Beginning in the 19th century, technological advances started making the production of steel cheaper while also improving the quality of the product, helping fuel the growth of American cities, railroads, bridges, and factories. With technological advances making it stronger and even lighter, steel is necessary to build future infrastructure.

Steel is a common and important building material because of the benefits it adds to a structure. It offers high strength durability, performance, flexibility, reduced weight, configuration adaptability and safety. It is also sustainable and cost-effective.

Benefits of Steel in Construction

Steel has not changed much since the 19th century. The reliability of the product is what makes it essential to construction. Steel is known for its strength, durability and efficiency because it can handle the wear and tear of outdoor environments. In addition, structures made from steel have longevity and require little maintenance. Another benefit of steel is that it does not need excessive space to support a structure, allowing for slender columns and better space usage.

Computer machinery has also made an impact on efficiencies in the steel industry. Prefabricated steel sections can be quickly produced in off-site fabrication shops, providing dimensional accuracy and ensuring that the steel used is the right size and density.

Steel can be shaped, cut and molded to fit different designs, making its versatility vital for all types of construction. In addition, it is one of the most sustainable construction materials due to its ability to be reused and recycled without experiencing any downgrade. Steel reduces the usage of nonrenewable minerals and does not require excessive energy or the use of harmful products. The recycling of automobiles, refrigerators and toasters, to name a few, has allowed steel to increase its overall strength and toughness, providing better resistance to heavy loads. The elements found in these products can include copper, titanium, nickel, chromium and manganese. When combined, it produces alloy steel, resulting in highly resistant properties against corrosion.

Test of Time

Steel can be installed anytime, regardless of the weather, which means projects can remain on schedule. In addition, the prefabrication of steel allows for dimensional accuracy, easy installations and efficiencies in reducing construction waste.

In addition, it is easier to modify steel buildings to accommodate new applications and vertical expansions. Engineers can effortlessly strengthen existing beams or add to existing steel-framed structures. Steel modifications can be done without the need to vacate premises, making steel construction ideal because it reduces costs and allows business to continue as usual.

RK Steel is the heart of many of RK’s construction projects. RK’s foundational knowledge in construction paired with RK Steel’s expertise in fabricating and installing structural steel, custom steel, metal products and miscellaneous metals, results in best-in-class projects.

Written by Ileana Morales

How Steel Can Improve Sustainability in Construction, accessed May 10, 2022, Nearby Engineers

Made in America: The Past, Present, and Future of the Steel Industry, accessed May 10, 2022, Boyd Metals

Pros and Cons of Using Steel in Construction Projects, accessed May 10, 2022, BuilderSpace.com

By: RK Energy

Modular facilities and skidded equipment are manufactured and assembled indoors, at a fabrication facility, affording companies the opportunity to produce high-quality units while decreasing costs and often accelerating the project schedule. Organizations are increasingly innovating their construction and procurement processes by purchasing modular, mobile, prefabricated facilities and equipment.

Save Time and Money

Equipment is contained within a modular facility or skidded frame that allows it to be easily transported. Individual skids can house complete systems, or multiple skids may be combined to create larger modules. In cases where there are logistical constraints, large modules are split into multiple pre-assembled units that are interconnected at the site.

An Alternative to Traditional Construction

System parts can be shipped individually and installed on-site as needed. Because the systems are built off-site in a fabrication facility, improvements can be completed at the plant site simultaneously. Skidded process systems provide several advantages over traditional construction process systems:

Portability: Units are self-contained within frames, making it easier for them to be transported. Systems can be moved to another location as needed.

Space Saving: Custom frames allow equipment layering. All of the necessary equipment is able to fit into a smaller area.

Accessibility: Skids often contain a hallway in the center with the larger pieces of hardware placed around the periphery.

Better Organization: Skids are organized into one area at the site, making on-site connections easier.

Off-site Assembly: Skids are built in controlled conditions at a fabrication facility. Operations taking place at the plant are not affected by the new system fabrication.

Factory Acceptance Testing (FAT): Testing is completed before systems are shipped. Equipment is ready to be used immediately upon delivery reducing startup time.

Maintain Productivity: Skidded systems allow facilities to remain functioning while maintenance is being performed.

Quality Control: There is a higher level of responsibility and quality control when a single party is responsible for the construction and installation of skidded equipment.

If you are interested in learning more about the advantages of modular facilities and skid-mounted equipment or systems, or if you would like a free project consultation, please contact us at rkenergy@rkindustries.com.

Denver is flourishing. Its population and employment growth are among the strongest in the nation, with the population almost tripling since 2000, according to the Denver Business Journal and the Downtown Denver Partnership. To accommodate the population and business growth, nearly $2.5 billion is currently planned or under construction in Metro Denver.

Steady Construction for the Foreseeable Future

Collecting accolades from Forbes as the best place for business and careers, and with U.S. News and World Report declaring Denver as the best place to live in the country, it’s easy to see why companies are flocking to Colorado. The city’s rapid growth means its infrastructure must quickly expand as well. New buildings have to be built and older buildings have to be renovated to keep up with the office and living space demand. In turn, construction project schedules are extremely tight with little room for error.

The structural support for these new and renovated buildings must be sturdy and stable as they are being constructed in the densely populated downtown area with heavy vehicle and pedestrian traffic. Developers and owners rely on contractors to hire experienced project teams to fabricate and install high-quality products to construct these buildings on a fast paced schedule.

Structural Steel is the Material of Choice for Commercial Construction Projects

The American Institute of Steel Construction says structural steel is the trusted material of choice for many reasons:

- Project Schedule: Prefabrication in a fabrication shop increases productivity allowing for rapid erection on-site and a decrease in wasted materials.

- Construction Budget: Steel costs 5 – 7{daeb8d662f58e4975bc93960761d671bdf0aa2ad049ea8a375d2717d280ef80b} less than concrete framing. Today, a single ton of steel requires less than one single man-hour to produce.

- Aesthetics: Steel is functional and unique, with natural beauty, allowing for creative designs. Exposed steel emphasizes strength and transparency.

- Design: Building Information Modeling (BIM) allows full integration between analysis, design, detailing and fabrication. BIM applications like Trimble are taking steel design to a new level.

- Sustainability: Structural steel is the most recycled material on the planet and can be reused without additional processing.

- Modifiable and Efficient: Steel can easily be modified or strengthened depending on requirements. It also optimizes building space efficiency through the use of columns and beams that allow for longer spans of open space.

- Reliable and Predictable: Structural steel is fabricated under controlled conditions using quality control processes. Its strength is verified at the point of production, not after the material is installed.

Industry Knowledge and Proper Training Create a Reliable Project Team

Safe erection of structural steel requires a knowledgeable team. Ensuring workers are qualified, suitably trained and have sufficient experience to perform work safely must be established and verified prior to starting work. The steel team should be in constant communication with the general contractor and other trades to plan site access, equipment needs and laydown requirements. In addition, developing site-specific work instructions and safety procedures to identify potential risks is key.

RK Steel is currently working on several projects in downtown Denver including Bock A, 17th and Wewatta, 1709 Chestnut, 14th and Lawrence, Denver Club Renovation, Helen Bonfils Theatre Renovation, Denver Center for the Performing Arts Galleria Rails, Confluence Park Tower, 1201 Auraria and the Residence on Cherokee. RK Steel is a single source for fabricating and installing any type of structural steel or miscellaneous metals such as stairs, rails, platforms and canopies. Do you have a project that needs a trusted, premier steel contractor to get the job done? Contact our team for a free project consultation today at rksteelestimating@rkindustries.com.